Meeting green challenges

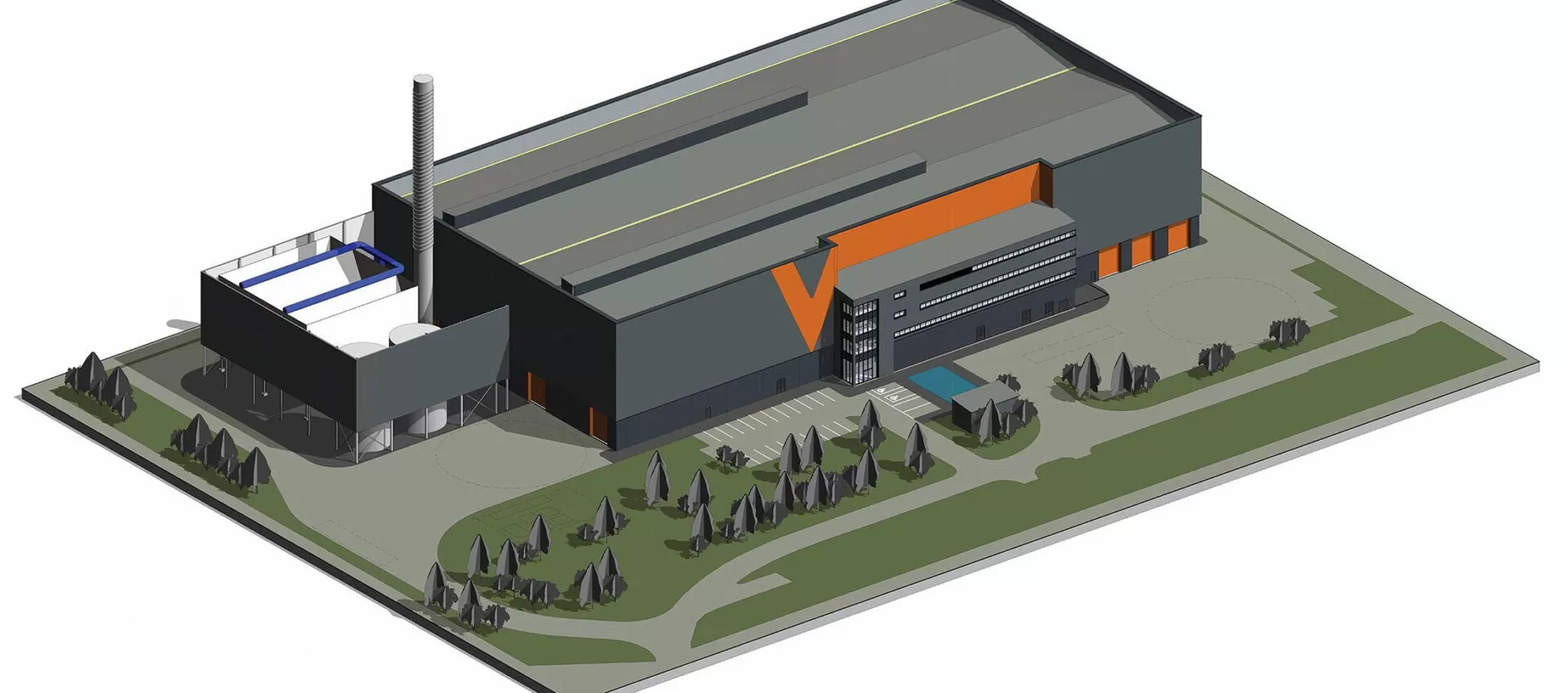

The site of an old power station near Burton-upon-Trent is being redeveloped by Vital Energi Group to become an energy-from-waste facility poised to add 18 megawatts of green energy to the grid each year, by generating low-carbon power from ‘non-recyclable refuse derived fuel’

A King Post Wall was required so that the space could be turned into an ash bunker. Unusually, the work was carried out indoors in a pre-existing operational building where restricted headroom was a challenge, so choice of plant was a significant factor in being able to deliver a suitable solution.

Using state-of-the-art equipment to meet the needs of our customers

The answer came in the form of our compact but powerful ultra-low emissions ABI TM13 Mobilram Telescopic Leader Rig. This versatile rig is able to work in challenging locations where space is at a premium, delivering unrivalled power in its class without compromising efficiency. In fact, this machine uses the latest technology to help reduce fuel consumption, noise and exhaust emissions, being equipped with a 209kW EU Stage V engine, giving optimised power delivery, coupled with unparalleled levels of fuel savings and reductions in emissions and carbon generation. The TM13 matches the driving power of larger rigs, but achieves it with a smaller more efficient engine, which also makes the machine easier and lighter to transport, further reducing overall fuel consumption and carbon footprint.

The installation method involved first augering down to the required depth through pre-cored holes in an existing floor slab. Following this, the auger string was extracted whilst the bores were filled with a concrete mix, pumped in using the CFA method to accept H-beams installed at regular intervals.

Universal columns were then plunged into the wet concrete using an excavator mounted vibratory hammer, and temporarily held in place by a tack welded steel ground beam to ensure verticality during the curing process. Once the concrete was cured, the tack welds were ground off and the steel beam removed ready for panel installation.

Delivering high tolerance installations

The spacing, positioning and verticality of the posts was critical and needed to be carried out to a high tolerance to ensure a good fit for the pre-stressed concrete panels, inserted to form the King post wall – testament to the skill, experience and know-how of our site teams.