Ivor King’s GRB System the way forward for a vibration-free, compact installation

The Stephenson Street Flood Defence Project on the Eastern riverbank of the River Usk in Newport, South Wales is a National Resources Wales and Welsh Government led scheme to protect homes and businesses in the area vulnerable to flooding, as a result of heavy rainfall and high tides.

The River Usk at Newport is both a Special Area of Conservation and a Site of Special Scientific Interest (SSSI), with only a narrow corridor from which to work and not enough room for a standard crane to operate. For this reason, Ivor King’s Giken Full GRB (or Giken Reaction Base) system was selected as the only viable method of installing sheet piles.

Not only is the GRB System eco-friendly, hydraulically pressing-in sheet piles noise and vibration-free, but it also works on the principle of a footprint-free installation. Compact and streamline in nature, all procedures, from pile transportation, to pile pitching, to the pile installation itself are carried out from on top of previously installed piles – ideal for sites with restricted access.

How it works

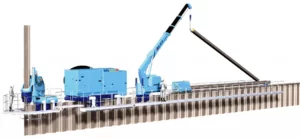

The GRB System consists of a Silent Piler and Power Pack (on a unit runner to transport the power source) at the front, followed by a Clamp Crane to pitch piles and a Pile Runner to transport piles from the storage area.

First, the pile runner, effectively a flatbed trailer which moves along on rollers, is loaded-up with sheet piles at the storage location. Once loaded, the pile runner, driven by remote control, travels back along the pile line, locking into position immediately behind the clamp crane. The clamp crane, which as its name suggests, is a specialist crane that clamps onto previously installed piles, lifts sheet piles individually from the pile runner, slews 180º and pitches them into the chuck of the silent piler. Finally, the silent piler presses-in the sheet pile using reaction force from previously installed piles.

After pile installation, the silent piler and clamp crane raise their main bodies and ‘walk’ to their next position, whilst the power pack and pile runner move along using their runners and roller assembles ready to repeat the installation process.

The GRB system eliminates the need for temporary platforms and workspaces for cranes, and is particularly effective on sites with limited access and tight, narrow working conditions, especially over water or on sloping ground.

This project saw us install 1000 sheet piles in total to form a new flood barrier, spanning a distance of some 600 metres, alongside the foreshore of the River Usk.

Steel capping beams manufactured by Ivor King complete the project

Sheet piles were topped off using a steel capping beam, manufactured in Ivor King’s workshops to design specification and welded into position. The capping beam will protect the people from any sharp edges once the footpath which will run adjacent to the sheet piles opened to the public.

For added sustainability, EcoSheetPiles were used on this scheme – manufactured with 100% recycled material and 100% renewable electricity.