We use state-of-the-art technology to offer Silent Giken Piling solutions. This solution represents a means by which sheet piles can be installed with vastly reduced noise and vibration, often called press-in piling or vibration-free piling. The press-in system operates by using the reaction from previously installed piles to resist the necessary force to drive the adjacent sheet piles.

Press-in piling is an excellent method for avoiding noise and vibration problems when driving sheet piles at sensitive locations. Sheet piles can therefore be installed close to buildings and boundaries, ideally suited to create more usable space in basements in property development. This solution has the potential to offer major commercial benefits, which can be of more value than the cost of the wall itself.

Noise Policy Statement for England

The Noise Policy Statement for England sets out the long term vision of government noise policy – to mitigate, minimise or avoid adverse impacts on health and quality of life through the effective management and control of environmental noise. As such, silent piling is now becoming the go-to standard way to install sheet piles, particularly in built-up and environmentally sensitive areas.

Ivor King operates two main types of silent, vibration-free press-in piling solutions:

- Silent Giken Piling (self-supporting press-in equipment)

- Hydraulic Press (Leader Rig mounted press-in system)

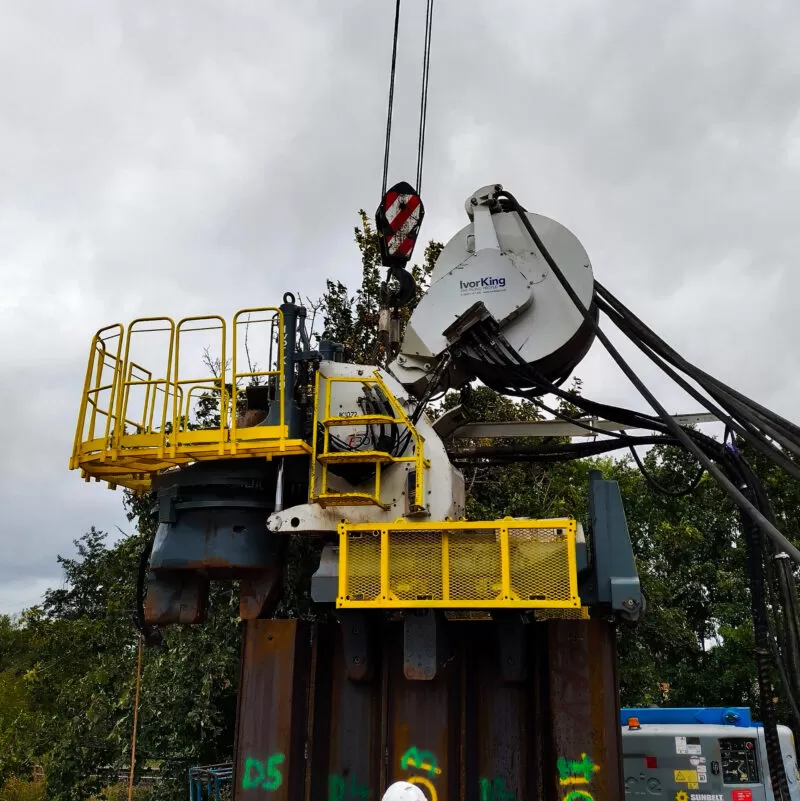

Giken Silent Piling Equipment

This cutting edge equipment has been developed to enable the plant to ‘walk’ over the tops of the driven piles. The system enables the Giken to be self-supported using the recently installed piles to generate reaction to enable pile installation and support the machine. The Giken is operated via a wireless remote control. These machines can work without a piling mat, up or down embankments, at height or over water.

These machines, which are especially suited for use in cohesive and granular soils, are hydraulically operated and derive most of their reaction force from friction between the soil and previously driven piles.

Our silent Giken piling equipment presses each successive pile to full depth, using a pitch and drive procedure, whilst ‘walking’ on the previously installed piles. The sheet piles are fed by a crane into the enclosed chuck (or pressing jaws) of the machine. The machine can guide and align the piles without the need for piling gates or wailings. Accurate alignment is maintained by using a laser light beam focused on the leading interlock of the pile being driven. The machine then raises its body and travels forward to the next position, without the need for crane support.

Ground Suitability

The machines work best in clayey, slightly cohesive or fine-grained soils. Should ground conditions become less favourable, the Giken Silent Piler can be equipped with a water jetting attachment, using low or high pressure water. In especially hard/dense ground conditions the Giken Supercrush attachment can be utilised. Water jetting is necessary to loosen fines in cohesionless strata or to lubricate dry cohesive soils. Pre-augering using the Giken Supercrush attachment can be used to loosen or mix the soil, allowing the pile to be progressed into the ground. Superficial obstructions are dealt with by digging a lead trench along the proposed pile line. The trench may then be used to control surplus water and arisings.

Giken Water Jetting Mode

This technique is used where SPT’s lie between 20 and 50 in both granular and cohesive soils. When pressing the pile into the ground a pressure bulb is created at the toe of the pile. The increase in resistance that this creates could affect the alignment of the pile and lead to loss of productivity.

To resolve this problem, high pressure water jets reduce the pressure bulb by temporarily and locally loosening granular soils and softening the cohesive soils. Simultaneously, the returning water lubricates the pile surface as well as reducing clutch friction, thus reducing the tendency of the pile to plug.

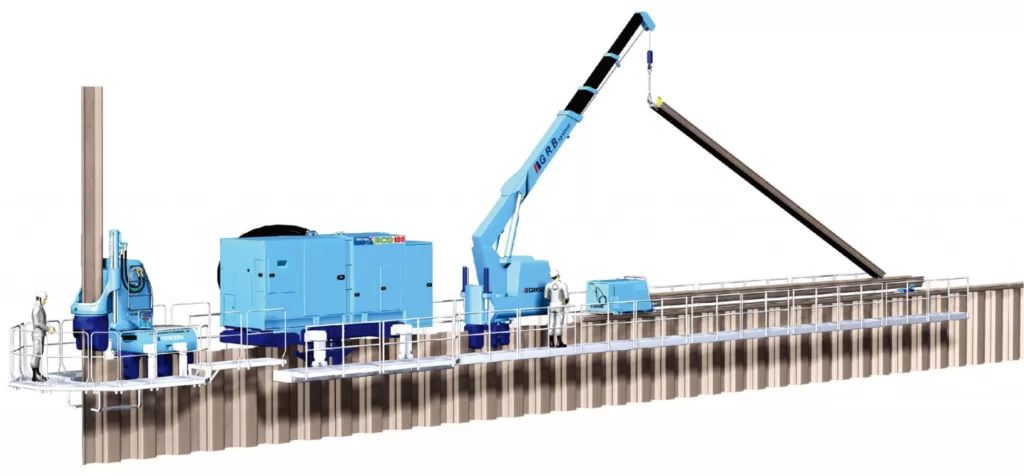

Giken GRB System

The Full GRB (Giken Reaction Base) System works on the principle of a footprint free installation. That is to say all piling procedures, including pile transportation, pile pitching and press-in work are possible from on top of installed piles.

The silent piler and power pack are followed by a special clamp crane which also sits atop the piles, to pitch sheet piles to the silent piler. Sheet piles are loaded onto a pile runner, which transports piles along the top of the previously installed pile line, ready for lifting into position by the clamp crane, which is able to slew in either direction.

Because this set-up is compact in nature, it is particularly effective on sites with limited access and tight, narrow working conditions, especially over water or on sloping ground.